Built with precision, ready to work

At Mackworth, we’ve developed a core product range for four of the UK’s most widely used commercial vehicle platforms under the Stellantis range. These vehicles form the foundation of many national fleets, and our conversion packages are built to ensure quality, consistency and reliability from day one. By refining and aligning our internal production processes, we’ve created a repeatable, controlled build model that gives customers confidence in both lead times and finished quality — without compromising on functionality or compliance.

The vehicles we convert as standard

Each body is manufactured in Derby using robust materials, precise engineering and type- approved components — making every build fleet-ready and regulation compliant.

Beavertail Bodies

Built for the safe and efficient transport of plant, machinery and powered access equipment.

Our beavertail bodies combine strength with easy rear loading, using proven materials and

engineered ramp solutions.

Standard Features:

- Galvanised steel and aluminium frame for strength and corrosion resistance

- Laser-cut underframe for a consistent, high-quality build

- Aluminium plank flooring

- Punched aluminium headboard panels

- Lightweight aluminium dropsides

- Assisted ramp hinges for safe and controlled rear loading

- Multiple rope hooks on both sides for load securing

Optional Extras

- High-level headboard storage cage

Luton Bodies

Luton bodies provide additional volume for bulky goods and high-capacity loads. Constructed from lightweight panels and featuring an aerodynamic cab pod, they’re ideal for delivery fleets and removal services.

Standard features:

- GRP or equivalent lightweight panel construction

- Aerodynamic cab pod for added volume

- Laser-cut modular subframe

- Aluminium body frame with galvanised steel rear aperture

- Hard-wearing WISA-Deck flooring

Optional Extras

- Barn doors or narrow lath shutter door

- Column tail lift or full enclosure tail lift

- Load lock and tie rails

- PIR (passive infrared) lighting

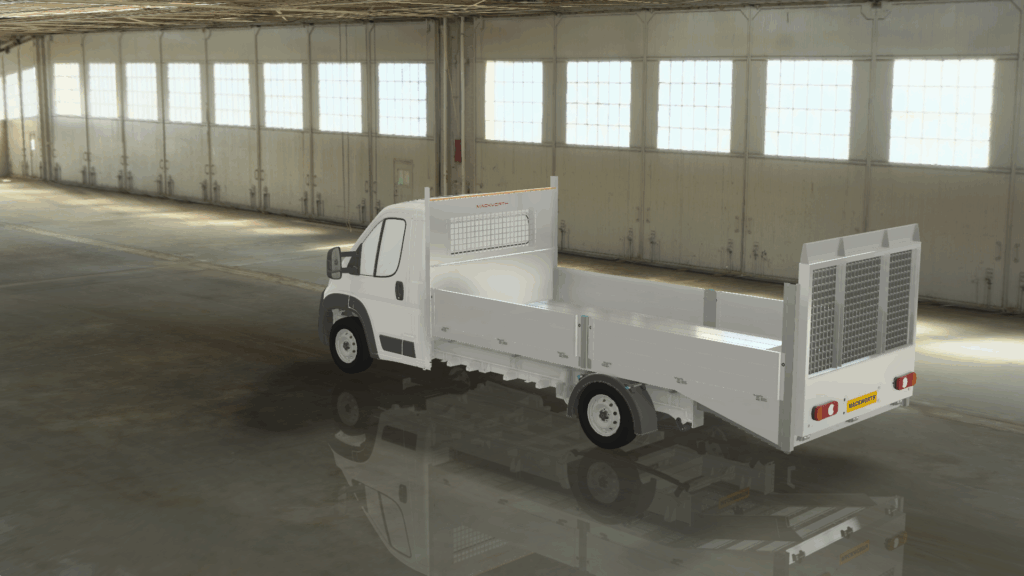

Dropside Bodies

A versatile solution ideal for builders’ merchants, landscaping, and highways work. Our dropsides are constructed using galvanised steel and lightweight aluminium sections, giving each body a long-lasting and corrosion-resistant finish.

Standard Features:

- Punched aluminium headboard panels for a modern finish

- Laser-cut underframe for a consistent, high-quality build

- Hard-wearing WISA-Deck flooring

- Punched aluminium headboard panels

- Lightweight aluminium dropsides

- Multiple rope hooks for cargo netting and load security

Optional Extras

- Aluminium cage sides with barn doors and roof

- Working at height rails

- Fuel lockers and toolboxes

- Chapter 8 chevrons and amber lighting

- Platform tail lift

- Towbar

Tipper Bodies

Designed for strength, stability and safe offloading, our tipper conversions are built to handle the rigours of highways, utilities and construction work. We combine tough materials with precision engineering to keep your fleet moving.

Standard features:

- Galvanised steel and aluminium body for a durable finish

- Electrohydraulic underfloor tipping gear

- Interlocking aluminium flooring – lightweight, strong and easy to clean

- Laser-cut modular subframe for efficient build and maintenance

- Lightweight top- and bottom-swing aluminium rear door

- Aluminium sideboards

- Rope hooks fitted along both sides

Optional Extras

- Cage sides with barn doors and roof

- Fall arrest systems

- Towbar, fuel lockers and toolboxes

- Dump-over tail lift

Over 60 years’ industry expertise

Fully managed conversions, built to last

3-year warranty on all Mackworth builds

Established 100% UK-based support

Why Choose Mackworth Vehicle Conversions?

We build a reliable range of type-approved conversions across multiple chassis types, all engineered to perform and built to last. Our team combines deep technical knowledge with practical, collaborative support to deliver vehicles that meet operational needs at scale—whether it’s a single unit or a full fleet roll-out.

- Technical Team Knowledge

- Collaborative Support

- Tailored Approach

Consistent quality

Every vehicle goes through the same proven build process, using the same trusted materials, fixtures and installation techniques. That means less variation, fewer delays, and vehicles delivered exactly as expected.

Faster turnaround

With key elements already engineered in, we reduce time lost on repeat design work or sourcing — helping you get vehicles on the road sooner.

Reduced admin

Because we know these platforms inside out, we can simplify specifications, paperwork and approvals — whether you’re ordering one unit or fifty.

Fully compliant

All builds are completed to meet type approval, and we design each conversion in line with current DVSA, FORS and manufacturer guidance.

Don't just take our word for it...

"Following the award of the tender, Steve ran through all the racking specifications to accommodate any changes needed and then invited us up to Mackworth to see the finished products for sign off. It was great to see these prior to delivery and be able to make last minute adjustments to meet our trades needs...

...The end product has met all our requirements on keeping payloads high while providing suitable, good quality storage. Our trades have also been really positive about the new racking systems following delivery and how well it suits them on site. Any aftercare issues have been promptly dealt with and resolved and we have been kept updated throughout the process."

"Marlowe Fire and Security have been working with Mackworth Vehicle Conversions for several years for all our vehicle conversion needs.

Mackworth provide a fantastic service with great communication, expert designers and a great finished product that our engineers find essential to organise their tools and stock."

"Working with the team at Mackworth Vehicle Conversions has been a smooth and straightforward experience. They’re friendly, easy to deal with and clearly take pride in their work – the end product is always high quality and built to last."

"The relationship is easy. The guys at Mackworth know our trucks inside and out. Whether it’s Peter in the office or their team in the workshop, we know that if we have a problem, we can call and ask, ‘is there any chance you can have a look at this for us?’ and drop the vehicle off the next day without any hassle. Their flexibility and proximity—just 20 minutes away—make a huge difference."

"South Staffs PLC operate a varied fleet, from VW Caddys to CR50 Crafters and dropsides, and Mackworth Vehicle Conversion Specialists have consistently delivered high-quality fitouts across all vehicle types. The team are always easy to work with, offering excellent communication, guidance, and support throughout each project. Over many years, their workmanship has remained consistently high, and the durability of the materials and quality of the installations are second to none. These conversions make a real difference to our day-to-day operations by helping our teams work safely and efficiently...

...While Mackworth may not be the cheapest supplier, the value lies in their expertise, attention to detail, and reliable aftercare. What stands out most is the strong working relationship we’ve built—whenever issues arise, they are resolved quickly and with minimal disruption, which is a huge benefit to our business."

!We are pleased to recommend Mackworth Conversions as one of our trusted providers, for compliant, fit for purpose, commercial vehicle body conversions.!

!The service from Paul and his team at Mackworth’s is second to none.

The communication from the team was regular and honest, which is priceless in our industry.

We had two high-quality builds from them, and I could not find any faults after a close inspection.

The overall service from the team has been excellent, and we will be using them again for sure. !

Compatible with popular extras

We’ve pre-configured these vehicles to support a wide range of optional equipment including:

- Tail lifts and ramps

- Tool storage, fuel lockers and safety signage

- Camera systems and telematics

- Chapter 8 livery and lighting

- Fall arrest and working-at-height solutions

A strong foundation for every fleet

We’re continuing to expand this model to other popular van and chassis platforms — ensuring more operators can benefit from Mackworth’s proven build approach.

Contact Us

Ready to discuss your next conversion?

Let's talk

Hours

Mon–Thurs 8:30–17:00

Fri: 08:30 - 16:00